Differential locks are an essential component to off-roading, rock crawling, and excursions over rough terrain. But how does a diff lock actually work?

Keep reading to find out how differential locks impact a car’s performance, as well as other components that enhance your driving experience and safety when off-roading and rock crawling.

What Is a Differential Lock?

A locking differential is typically used in motor vehicles to “lock” the wheels on an axle together. This means that regardless of the traction on each of the individual wheels, both are going to turn in unison. Differentials can be locked or open. When unlocked, they allow each wheel to turn at different speeds, therefore avoiding premature wear on the tires.

2 Types of Differential Locks

Different vehicles utilize different types of differential locks. These can be grouped according to how they are operated. Here are a few kinds of differential locks.

1. Automatic Differential Locks

These are a type of differential lockers that do not require the driver's input to lock or unlock. Automatic differential lockers can detect when one wheel needs to spin faster than the other when the vehicle is taking a corner. In such circumstances, it acts to unlock that wheel. There are several advantages associated with automatic differential lockers. The key one is that the entire process is automatic, which means that the vehicle does not need to stop to engage or disengage the differential lock when road conditions alter.

The downside to automatic differential locks is that they can cause oversteer and understeer under certain driving conditions. Automatic differential locks are also associated with increased wear of your tires.

2. Selectable Differential Locks

With Selectable Differential Locks, the driver has the option to lock or unlock the differentials themselves manually. The driver has a switch that they can flip in the cabin, but the actual locking mechanism is achieved in one of several ways. It can be mechanical, an option that uses pneumatics or compressed air. Some vehicles have differentials that are cable operated. In recent days, vehicles utilize electronics to get the job done.

Selectable differential locks offer the driver complete control of the differential locking system. This, in turn, improves the vehicle's handling and reduces wear and tear on the tire.The downside to selectable differential locks is that the driver must actively anticipate the terrain ahead, which may not always be possible. The other downside is that some differential locking mechanisms require that the car come to a complete halt before being engaged. Finally, if a driver forgets to unlock the differential lock on road surfaces that do not require it, it leads to intense strain on the driveline components.

Choice Between Open Vs Locking Differentials

Whether you choose open or locking differentials is mainly dependent on the driving conditions you anticipate. Open differentials work great in vehicles that are not used for heavy towing or don’t operate on rough roads. Having open differentials allows the system to distribute the vehicle's torque equally across all the wheels, which enables the vehicle to achieve higher speeds.

Slips are also unlikely when you are cornering as the outside tire goes further than the inner one, thus stabilizing the vehicle. The downside here is that your car is likely to be underpowered if one of the wheels is slipping.

You should be aware that 4WD and AWD vehicles can feature a center lock. This is to split the speed difference between the rear and front axle. When it comes to 4WD cars with automatic differential lock, this center lock typically goes into action when the vehicle is about to lose traction.

2 Other Types of Differentials

Given the advantages and disadvantages of open and locked differentials, engineers have designed other variations. These are designed to make the most of the first two differentials while minimizing the downsides. The other designs of differential are Limited Slip Differentials, and Torque Vectoring Differentials.

1. Limited Slip Differential

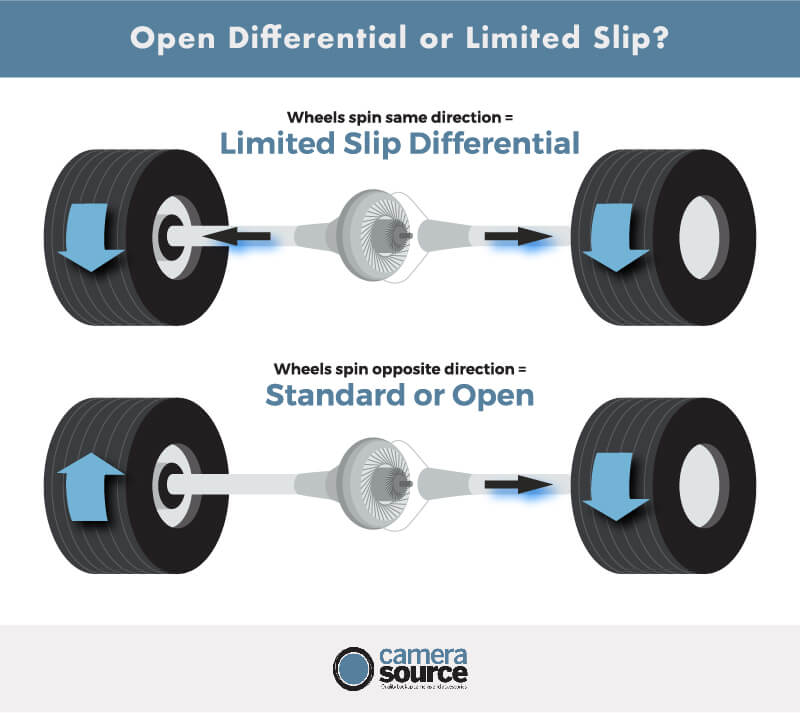

Limited Slip Differentiall, or LSD, allows the two shafts to spin at varying speeds, but the mechanism limits the upper difference between them. While vehicles with LSD offer better ride dynamics than the standard differential, they also have greater complexity.

The idea behind LSD is to fix a critical problem that vehicles with locked differentials face. When one of the wheels is on a slippery surface, it tends to spin. This, in turn, means that the wheel is not providing any power to move the vehicle but is absorbing power nevertheless. In the meantime, the other wheel gets the same amount of power as the spinning wheel.

Since the other wheel is the only one with a grip on the surface, it theoretically should move the vehicle. However, since it shares power with the spinning wheel, its power allocation is too little to drive the car. This means you could get stuck when off-roading.

LSD solves this problem by ensuring that no excess power is allocated to the spinning wheel, ensuring that the vehicle's traction is substantially improved. This is particularly important for climbing over rocks and uneven terrain without getting stuck.

2. Torque Vectoring Differential

Another type of differential is torque vectoring differential. The system is an electronic system to vary the torque sent to each half shaft. This relatively new technology is increasingly being featured in AWD vehicles.

With a torque vectoring differential, the system can independently control torque to each wheel. This, in turn, means that the design features both a traditional mechanical system and an advanced monitoring system.

While this system adds a layer of complexity to the differential, it makes for a more intelligent distribution of torque based on driving conditions. For example, a torque-vectoring differential system allows a vehicle to induce oversteer or understeer to help manage cornering dynamics. The system can also correct these two should they occur when not needed. The result is a much more sophisticated cornering ability and a much smoother ride.

Camera Source For a Safer Ride

Similarly to diff locks, backup cameras and front and side cameras enhance your driving experience and safety when off-roading and rock crawling. The multi angle view of your surroundings that automotive cameras provide can get you out of a jam and keep you out of one in the first place. We even have agricultural cameras and heavy duty cameras that can withstand excessive vibrations for extra rugged terrain. Start browsing our selection, or get in touch with us today!